Wedge Wire Screens

Manufacturing Process

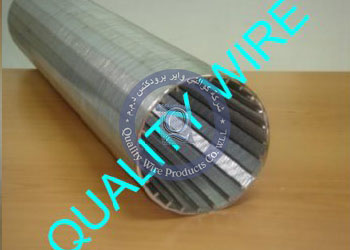

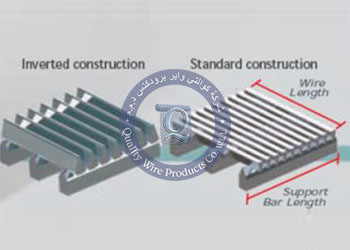

- Wedge wire is made from rigid triangular wire which is welded onto a support rod these rods are then mounted onto a Circular Die. The welding process includes welding done with a circular disk at each point in a continuous manner in order to form a tubular form. These screens could be employed in both tubular and slightly opened and flattened depending on the requirement.

- Our company is offering screens with a wide range of dimensions with a radius ranging from 12mm to 650mm with the length ranging from 2.4 m to 6 m depending on the requirements of the customer.

- We are also providing choices for the material used for making screens.We offer screens manufactured from Stainless Steel 304L & 316L & 904L; SS321 & SS410. We also offer special nickel alloy material like C276; alloy 600 & 800 & super duplex and duplex alloys.

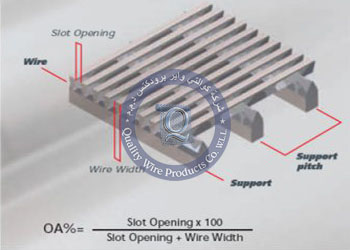

- For different models of wedge wire screens, we offer a slot opening in the range from 50microns to up to 25 mm.

Design

Wedge wire Screens are generally manufactured in two types

We design the products according to the needs of the customers and requirements needed. While designing a screen we consider factors like the type of plant and the requirements in order for us to offer a complete screening solution, keeping this in mind we offer.

- The complete detailed drawing.

- Detail support calculation for the entire load on the screen.

- Detail engineering calculation involving process and wedge wire design.

- Onsite installation team and step by step installation.

Uses

A typical wedge wire screen could be used as a

- Well Pipe screen

- Screens for sugar and coffee separation

- Header & laterals

- Top Distributor/ Outlet collector/bottom support screens

- Catalyst support screen

- Support grids with additional reinforcement

- Screens for reactors and Molecular sieve

- Flat panel screens with additional reinforcement

- Nozzles for charcoal absorber

- Resin trap for strainer housings

- Conical strainer type screens for sugar industries

Features

With the advancement of modern technology in the field of welding, we are able to use different wires with varying slots on a particular wedge wire screen. In the same way, we are able to produce different distances between supporting wires.

Wedge wires are made of welded steel structures and are used extensively for applications such as filtration. The surfaces are generally made into V-shape. The filtrate flows through the slots which are created by controlling the distance between surface profiles.

Wedge wires are used for a variety of uses such as separation of solids from liquids, filtering, sizing, collecting, distributing, retaining media and dewatering.

Benefits

The benefits of using Wedge wire screens are as follows-

- Strong construction.

- Easy to clean.

- Low-pressure- drop.

- Non-blocked- up.

- High-precision slot sizes.

- Support / Troubleshoot

We offer one of the best team of trained engineers for troubleshooting your problems and deliver our expert assistance during installation and troubleshooting of the screens at your site, which is offered free of cost depending on the nature of the project.

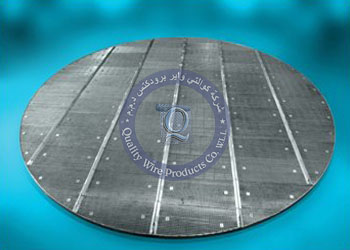

Wedge wire screen Catalyst Support Beds from 500MM dia to 8500MM dia

Gratings and Wedge wire screen – combination bed

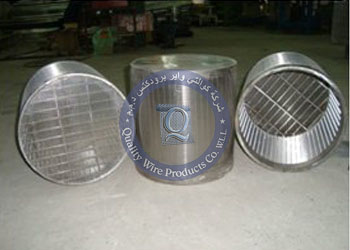

Wedge Wire Screen distributors and collectors

Wedge Wire Screen Nozzles